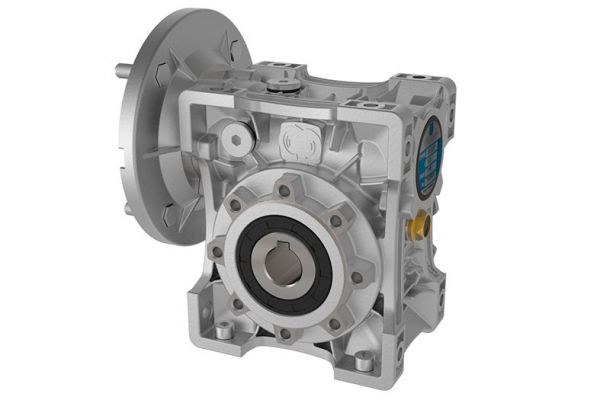

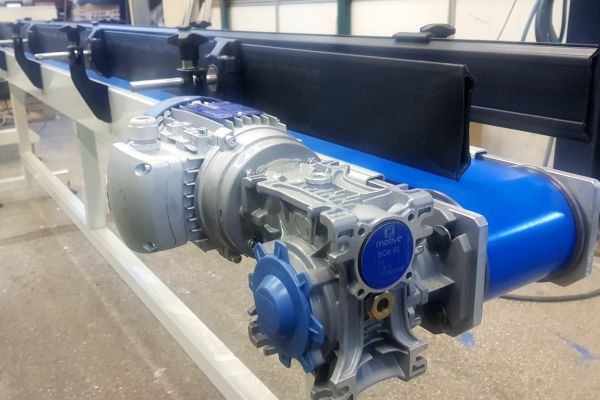

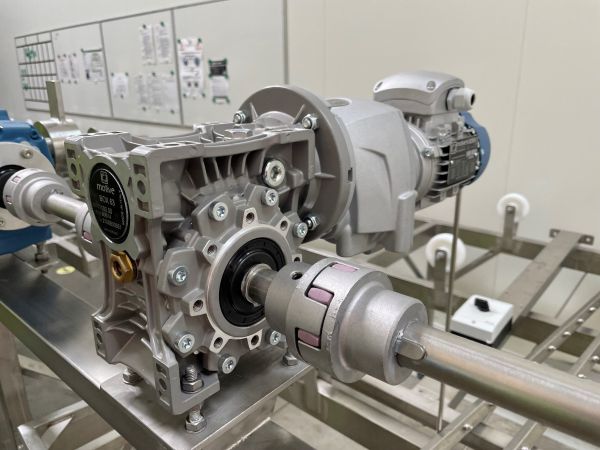

The patented “BOX” series of worm gear units is made with die-casting aluminium housing from size 25 up to 90, and in cast iron from size 110.

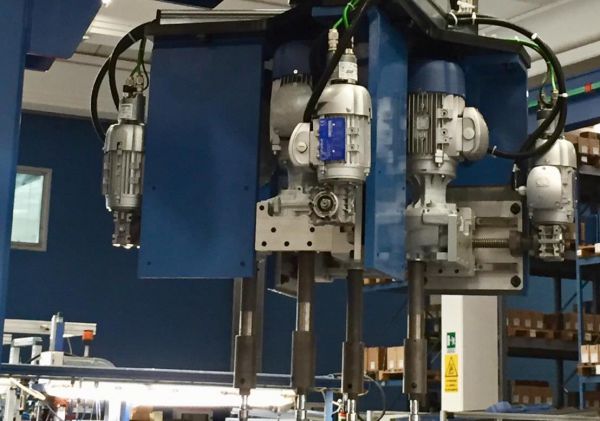

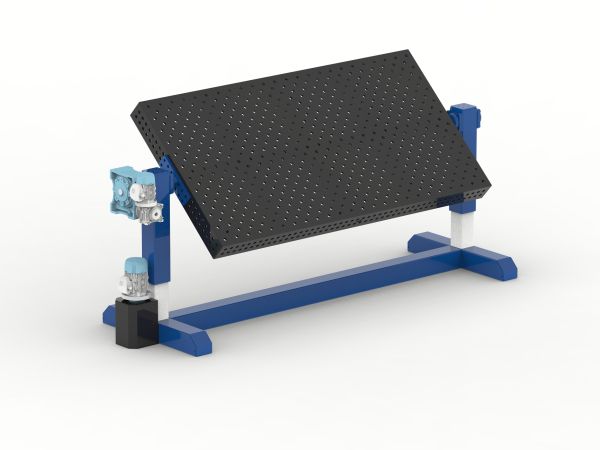

The whole BOX series can be mounted in any position with no need of specifications in the order

| BOX | motor type | max Nm (4 poles) |

| 25 | 56 | 13 |

| 30 | 56-63 | 19 |

| 40 | 63-71 | 39 |

| 50 | 63-71-80 | 74 |

| 63 | 71-80-90 | 135 |

| 75 | 80-90-100-112 | 205 |

| 90 | 80-90-100-112 | 360 |

| 110 | 90-100-112-132 | 675 |

| 130 | 90-100-112-132 | 850 |

| 150 | 100-112-132-160 | 1200 |

Designed and registered by Motive in 2004, the BOX worm gearbox series has become a design icon in the world of mechanical power transmission.

The Chinese copies now sold by importers as a “new modern design” are nothing more than the same design created twenty years earlier by Motive.

But the real BOX is not only more refined — it is also the most reliable, built with better materials, higher controls, and Italian quality that no imitation can match.

⚠️ Beware of imitators: importing or selling Chinese copies of a registered design may constitute violations of industrial property rights or competition laws, and lead to legal liabilities.

From type BOX75 upwards, 2 tapered roller bearings are mounted on the the tapered shaft, which improves the mechanism and mechanical resistance to axial loads given by by the bevel gear. In addition, the combination of 2 tapered roller bearings with 2 nilos (mounted on sizes 75 upwards to keep the lubrication, grease, inside the bearings even when they are not touched by the oil bath), or, alternatively, special RS shields on such tapered bearings, allows the entire BOX range, from size 25 to size 150, to be mounted in the V5 and V6 positions without the need for additional interventions.

The BOX series endless gearboxes are constructed with a die-cast aluminium housing up to size 90 and cast iron from size 110 upwards. The structure has been designed using three-dimensional parametric SW CAD and with the help of heat dissipation capacity and structural deformation/rupture resistance analysis programs under the effect of operating torque and external loads, with positive results in terms of sealing surfaces.

2 protected bearings on the output output shaft allow mounting in position B6 or B7 in series. In conclusion, the entire range can be assembly in any position without further specification in the order form

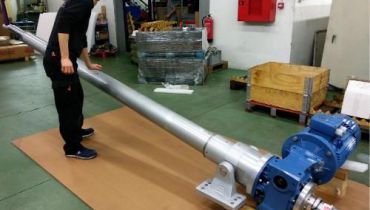

The special shape of the carcass has been designed to optimize water drainage during washing and avoid stagnation

Gearboxes up to type 90 are supplied by Motive lubricated for life with a synthetic oil, while from the type 110 and above, mineral oil is used. A vent plug is supplied as standard. The blind and level plugs are fitted by Motive in all possible Motive in all possible positions, facilitating customer stock management for the customer, who can decide at a moment's notice position at the last moment by positioning the plug before before commissioning.

To increase soundproofing, efficiency and service life the worm is case-hardened, hardened and the teeth ground, the worm gear helical crown is made of a special bronze alloy ZCuSn12 bronze alloy. The worm wheel's standard hollow shaft is made of spheroidal cast iron, an alloy that offers superior performance to gray cast iron, and is also suitable for intensive use

A coat of epoxy paint paint cancels out the effects of surface porosity of aluminum surface porosity of aluminum oxidation.

The mounting faces are milled to ensure perfect flatness for mounting.

Manuals

Catalogs

Download: BOX worm gearboxes Download: NEMA BOX SERIES WORMGEAR UNITS Download: General Catalogue

Altri Link

Buy online: Buy online