A New Milestone for ATEX Motors

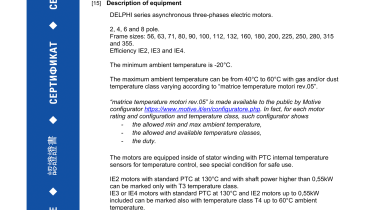

Enhancing Category 2 ATEX motors for high-risk atmospheres is no small feat. Delphi motors were already engineered for all gas and dust groups, with internal and external temperatures capped at 135°C. But we didn't stop there – we took innovation to the next level.

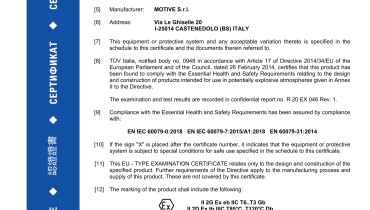

TÜV has certified motors from numerous manufacturers over the years, but our latest advancements even took them by surprise. Here’s how we set a new benchmark:

✅ Minimal Heating – Even at reduced voltages, including on the rotor (which typically heats more than the stator), thanks to ultra-low power losses and a high service factor.

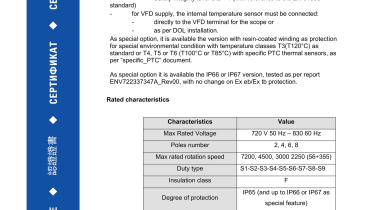

✅ Seamless Inverter Operation – Consistent, optimal performance with any inverter brand and across all service duties.

✅ Superior IP Protection – Enhanced ingress protection, ensuring long-term reliability.

What’s New? Groundbreaking Certification Achievements!

- Cooler in Higher Temperatures

Standard IE3 and IE4 ATEX motors maintain T4 gas class temperature limits (135°C), but now feature reduced dust surface temperatures (from 135°C to 120°C), despite being now certified for ambient conditions up to +60°C.

- Introducing T5 and T6 Versions

Our new T5 (max 100°C) and T6 (max 85°C) models are exceptionally cool, perfect for gases with extremely low ignition temperatures.

- Lower Surface Temperatures for Enhanced Safety

Standard temperature drops from 135°C to 120°C, with optional reductions to 100°C and 85°C, ensuring maximum safety in hazardous dust environments.

- Certified Safety Across All Operating Conditions

From classic S1 constant load to challenging S9 duty cycles, safety is guaranteed.

- Universal Inverter Compatibility

Our motors are safe and reliable with inverters from any brand, provided specific technical standards are met.

- Enhanced IP Ratings

Now available with IP66 and IP67 certification and resin-coated windings for superior durability.

A Step Forward in ATEX Safety, Reliability, and Performance

To learn more, click here